Tech Packs and local manufacturing – oil and water?

Much has changed in the last few years. We are pretty happy to see a strong push to bring development and manufacturing back on-shore. There is little doubt that many in the industry have, for the first time in a long time, danced a little jig.

But it isn’t all smooth sailing. Not everyone in the industry has the know-how or energy / time to deal with those who are new to the process, or those who are trying to bring their off-shore ways back on shore.

The advent of tech packs is the bane of our existence. Let’s be clear, they are an off-shore invention and generally speaking are not necessarily used by the industry here. I would like to explain why.

There have been any number of businesses pop up in the last little while offering tech packs and billing them as “the only thing you will need to get your <insert product name> manufactured”. To be blunt, that is not actually true.

Sure, if your intention is to make off-shore in big numbers, you will probably need a tech pack. If you are intending on making in Australia, do us all a favour and don’t get one made. You will be thoroughly disappointed when we tell you it isn’t actually of much help.

What is in a tech pack

That depends on the experience and skill of the person(s) making it for you. As a general rule, it should contain the following:

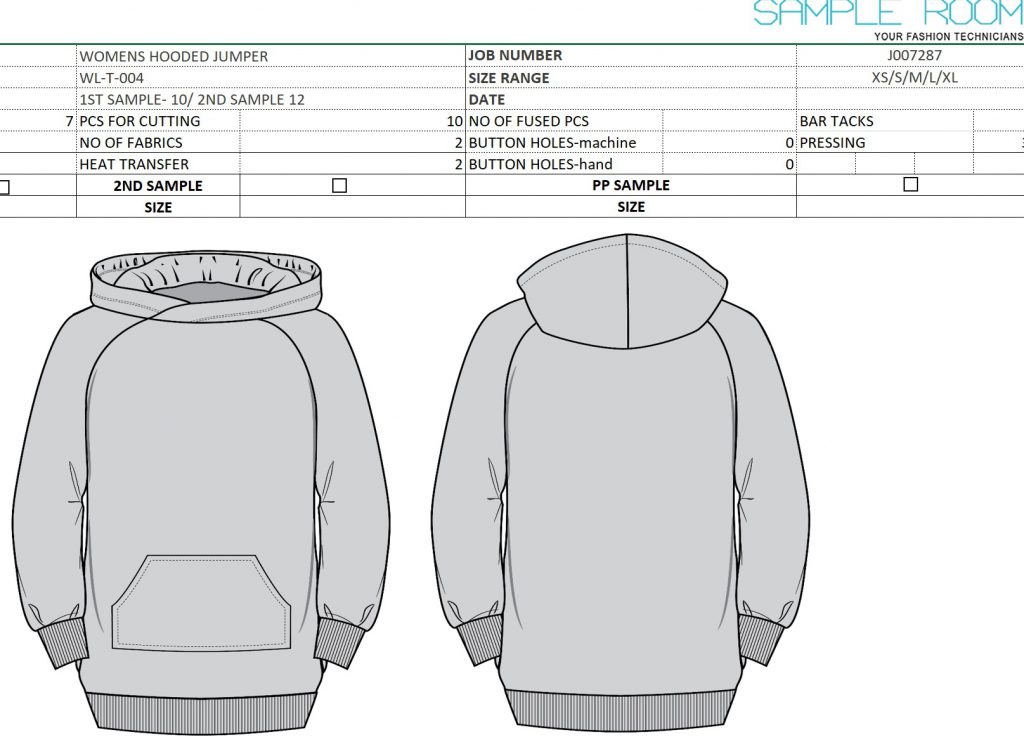

- Technical sketch

- Detailed measurements

- Fabric details

- Trim details

- Make details

- Label placements

- Spec or Key measurements

If it doesn’t contain ALL of these things then it definitely is of little use.

Why we don’t use them

If you start your development process with a tech pack, you’ve probably just spent a lot of money for a “draft” document which, by the time you are done with development, will have had most everything in it changed.

We hear from many people that they are ready for production because they have a tech pack but really they are ready for the development stage. A tech pack is an instruction manual for a pattern maker to make a pattern and a sample maker to make a sample. It is used offshore so language is not a barrier and the factory have some hard facts to follow, even if they are incorrect, so you can’t blame a misinterpretation.

The biggest issue I have with a tech pack being developed by someone who is not making the pattern is there are often gapping holes or contradictory information. It could be that measurements are given that can not possibly be used together, for example the armhole drop, side length and overall length are out by 2cm or the graded measurements have followed a formula but are not correct. Or an across chest measurement is given for a stretch garment when we don’t know yet how stretchy the fabric is.

You see, the development process is an iterative process that needs to consider a whole host of things, decisions which YOU need to discuss with a pattern maker, in order to get to an outcome that you like / love. Fabrics, trims, fit, make details, all the things which can ONLY be known once a design meeting is underway. As all fabrics react differently and how the garment / product is put together has an impact on this, no ‘expert’ can know this until is it done.

At the point where development is finalised, then, and only then, can a tech pack really be a useful document.

Source of truth

A tech pack on its own can be a dangerous thing to rely on. Full of measurements and details that remain open for interpretation. How do we know this? Decades of experience using them and beating our head against a brick wall.

The real source of truth is a combination of:

- Graded Pattern(s)

- Samples

- Detailed specifications and make details

- Graded specs that have come from a final graded pattern

- Fabrics

- Trims

- Labels

Armed with these things, you help remove the interpretation and it gives a manufacturer a MUCH clearer picture of what they are making numbers of. Missing one element raises the stakes and opens the door to someone having to make a decision which may, or may not, work in your favour.

Why risk it?

Want to know more? To find from an expert why we simply won’t use tech packs? Want to know why you learned to make tech packs at university / college?

Join Julia for our Manufacturer Discovery Masterclass.