Pattern Maker Melbourne - Serving Experience Labels

Local development and production is the new black.

Is this something you are looking at doing? A little bit unsettled by what is happening on a global stage and how that impacts your next range, your margin or just simply your ability to supply your customers?

Sample Room is a specialist in development, having opened our doors in 2009 specifically to help labels develop their styles locally and ethically. Giving the designer much more control and regaining valuable time to focus on other value add tasks.

With a team of highly experienced pattern makers, cutters and sample machinists, Sample Room is highly adept at all elements of development, from pattern making, to sampling, to detailed specs or tech packs (if you still need them). Our focus has always been on very high quality output with the minimum of time, effort and expense for you.

Are you having difficulties with:

- Getting samples from China

- Communicating with your supplier

- Can’t get production out of China

- Can’t or don’t want to go there and solve problems or perform QC

- Frustrated with lack of control over the situation

- Stuck using the same factory when you really would like to change

- Customers are looking for more Australian made

- Need quicker turn-around times

Could you imagine if:

- You could discuss your design with a pattern maker face to face to get your ideas across quickly and clearly without the need to create full graded specifications in advance

- Have your designs Pattern made / Sampled / altered / graded / and graded specs created in under 10 weeks

- Owning your patterns for flexibility and agility in where you manufacture- locally or overseas

- Owning your patterns in DXF format for multiple pattern making systems with specs that match the pattern precisely – no more guessing

- Having your styles manufactured by an Ethically Accredited manufacturer

- Talking to someone in Melbourne in their workroom who will be making the pattern and the sample in house.

This is how we can help:

- We can develop your product in our Collingwood studio in Melbourne.

- Our Pattern makers and Sample Makers work 3 meters apart, so problems are solved immediately before you have seen the garment saving you time and running around

- Reduce your sampling down to 2, because of the communication, convenience, and experience

- No need to digitize the pattern in for grading as we are computer pattern makers

- We can trace off your garment and create the pattern, so you have accuracy and consistency for your customer

- High tech scanning equipment of patterns for quick accurate scanning

How we can help

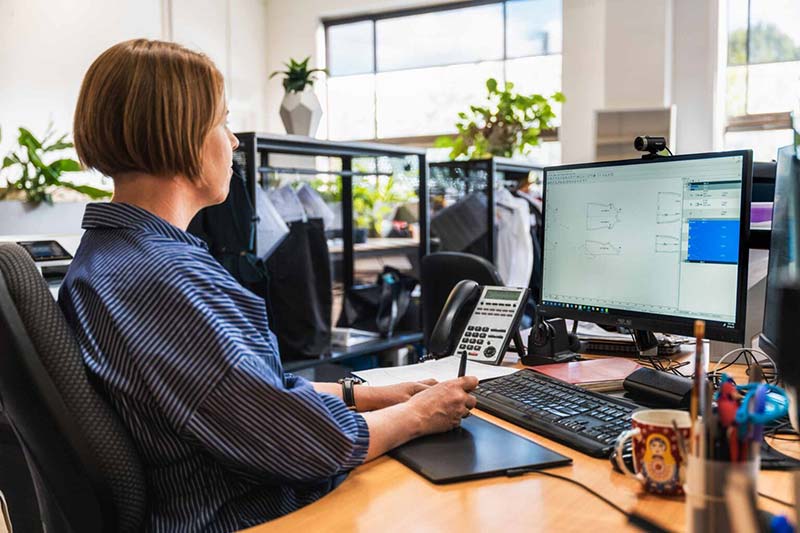

Pattern Making

A team of experienced computer pattern makers with over 50 years of manual and computer pattern making knowledge in Men’s, Women’s, Kid’s garments and accessories.

Sample Making

Highly experienced in-house sample machinists who work closely with pattern makers to help ensure exceptional samples. Talented in everything from swimwear & lingerie to evening gowns and everything in between.

Pattern Grading

Combining 50 years of pattern making experience together with exciting new technology provides highly accurate graded patterns and markers.

Specifications

Bringing together the all the elements and drawing on skills of a highly experienced team, specifications and tech packs that set industry standards.

Production

Our team has more than a combined 150 years of experience in manufacturing everything from t-shirts and activewear through to evening wear, all to the highest quality.

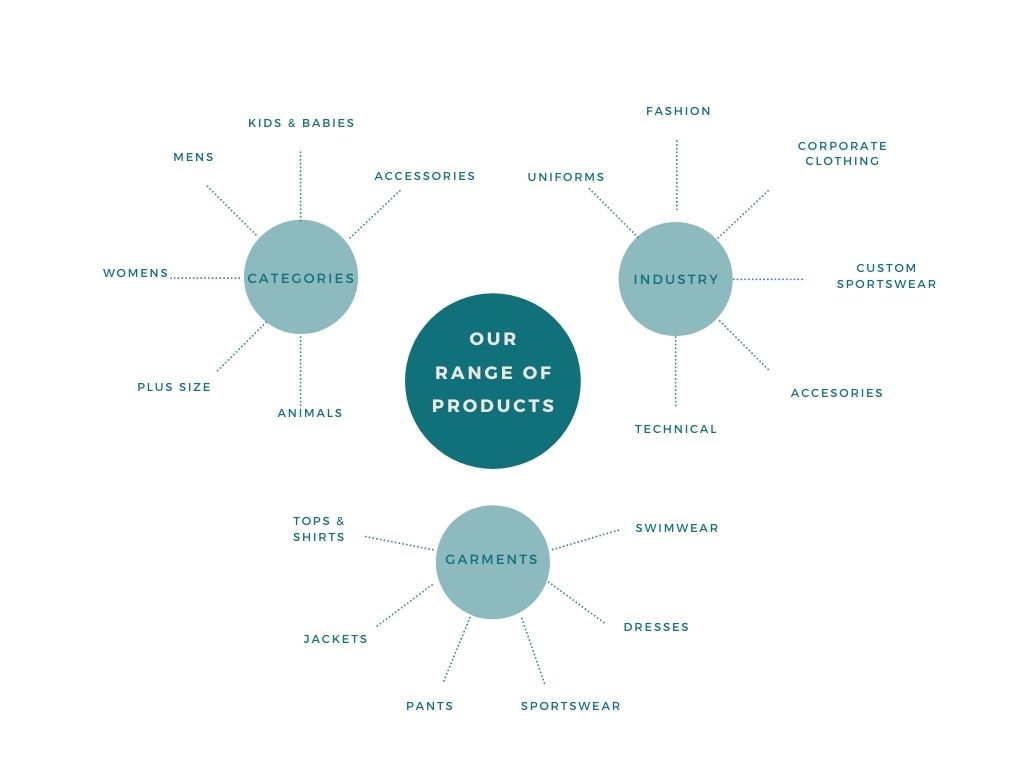

A wide range of products and services

Pattern making, sample making and grading for a range of clothing and textile product Categories, Industries and Product offerings.

We can help you create a smoother, easier process of development through to manufacturing.

There are many and varied pathways for a variety of products.

Contact us to ask us how.

Looking for industry ready patterns only?

While Sample Room offers one-on-one services to designers, if you are looking only for patterns for a range of basics and activewear, have you seen the offering by our sister company Pattern Room?

Industry ready patterns in a fraction of the time and cost, but without the ability to modify or personalise. This is an ideal way to build your basic library with the minimum of fuss.

Head to www.patternroom.com to find out more

Off-shore vs On-shore

Ethical Clothing Australia

We are proud and excited to become one of the few pattern making services to have gained ethical accreditation via Ethical Clothing Australia (ECA) for our local production. If you would like to know more about ethical accreditation or other suppliers in this unique manufacturing process then please get in touch with ECA. ECA works closely with legally compliant manufacturers in Australia to ensure a transparent and ethical textile, clothing and footwear industry. The Sample Room works collaboratively with ECA as part of its ongoing commitment to offering ethically made products in Australia. ethicalclothingaustralia.org.au