Colourways – What Does This Mean?

The language in the fashion industry can be daunting if you are considering the new and exciting pathway to being a designer. Language, specific terms, and acronyms all create an environment that makes it hard to delve into.

But we’re here to help you, to guide you, so that your entrance into this new world is smooth and seamless (pun intended). So, here’s another word in fashion that you’ll hear quite a lot, but you may not know exactly what it means: colourways or colour grids.

What are colourways? Where are they used? What does it mean, precisely?

Colourways are different colour combinations that are used in the same design. For example, you might create a dress in navy and white, and offer it also in navy and red. This is known as two colourways. These options are created for your customer to have more choice by each design.

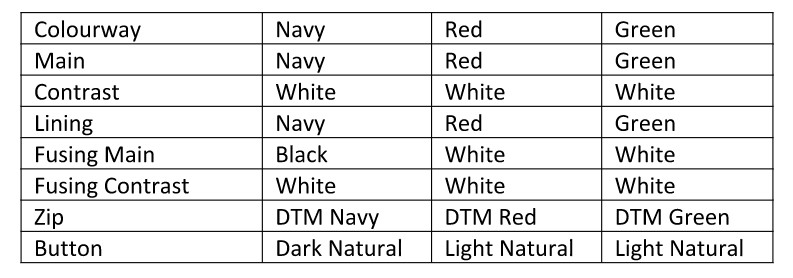

For each colourway it is essential for production that you create a colour grid to keep track of the colourways you are offering for your garment and so your manufacturer knows how you want your garments to look in production.

Here’s an example of a grid:

However, it’s often not as simple as our example above. It is important to test elements of each component. Fusing colours (which only come in black and white) can change the look of a fabric colour. You might find that you need to fuse the whole panels rather than part panels so there is no change in colour. For example, the back panel of a jacket that might have a back yoke fused in black may need the whole panel fused in cream to ensure it looks even and allows an even amount of colour through. You can test this yourself. Cut a panel that is about 60cm x 60cm and press a square of fusing of 20x20cm in the middle. Put this up against the fusing and then drape over a colour fabric to see if it is noticeable.

Another aspect of colour in production is thinking about the manufacturing minimum order quantities by colour. Keep in mind that all the machines required to sew the garment need to be changed per colour run, therefore colours cannot be sewn together in the same production run. It is possible to cut all colour ways together to save production costs, most of the time. A situation where you would need to cut colour ways separately is with components such as fused panels or different combinations.

Introducing different colours ways to your range is a great way to expand your product offering without extra money spent on development costs. When it comes to production runs, remember to have specific planning for the style quantity in each size for each colourway. The machinist will do all the sizes in the one colourway, then switch the threads on the machine for the next colourway, and so on.

And the last bit of advice is to test for colour bleeding in each colour way. Red has more of a tendency to bleed into white. A quick test of cutting the two fabrics, putting them in some hot water and then leaving them on top of each other to dry is a great way to see if the colours bleed, or will do so in production.

Working with colourways in your designs at first may seem daunting but, with experience and time, can be fun and eventually your own intuition will guide you. You will soon understand that the same design in a deep blue might look strikingly different in a yellow tone. Equally, as a designer, you will soon gain a richer knowledge that different colours will bring out different feelings and emotions in your customers.

We hope this has given you some unknown knowledge around colourways. Remember that we are always here to guide you. Look at our website for ideas, information sessions and webinars; sign up for our newsletter – you won’t miss a thing! And good luck.